Installation Guide of Worm Gear Tool Holder

- Manual and Help Files

* Use within the limits specified in the technical data, as per the clamping lists.

* No-considering the minimum clamping depth may result in damage and loss of accuracy.

* The clamping range of our tool holders are suitable for tools with symmetry of cylinder axis.

Axis type: DIN1835A, BDIN 6535 HA, HB

Shaft tolerance: h6

* Please use suitable protective gloves when changing tools.

Notice: If the minimum clamping depth is not observed, there will be risk of breakage (caused by parts popping out).

When the tension of the tool is released, hold the tool well to avoid falling off, damaging the tools and workpiece.

Step 1. Before use, please clean the inner cone of tool holder, conical surface and hole of collet with suitable things. (attention: Avoid dirt particles entering into the worm wheel during cleaning.) Insert the tool inside the collet, adjust the length of tool with the limit screw of collet. (Limit screw is optional accessory, not neccessory part.)

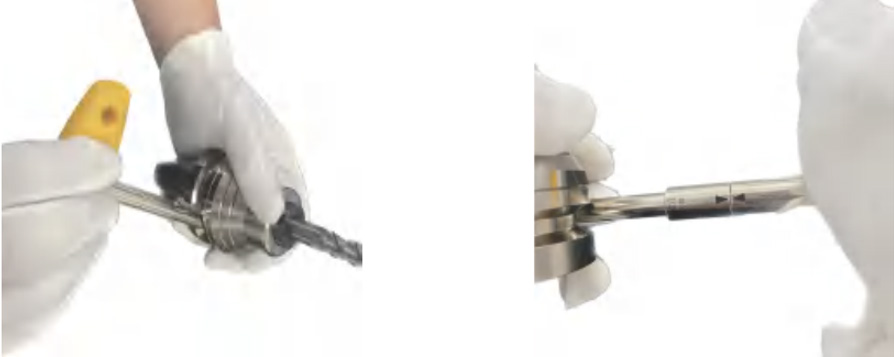

Step 2. Assemble the collet into the tool holder with hands, turn clockwise until the collet is connected to the cone.

Please clean the external and internal cone surface of both collet and tool holder, in order to have the best accuracy and gripping force.

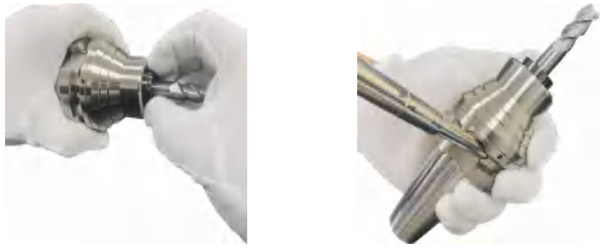

Step 3. Insert the torque wrench into the worm position on the side of the tool holder, turn the wrench clockwise direction, untill the arrows on both sides of the wrench are aligned.

(Please use our factory original torque wrench, to avoid any problems caused by torque instability. Please check the sides of wrench to make sure no damage before using.)