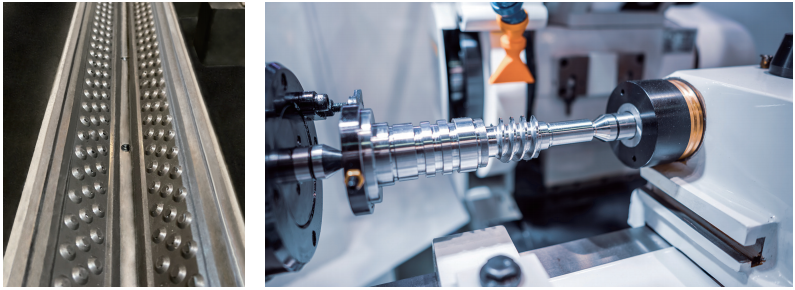

Wear-resistant coating

The low friction wear-resistant coating is composed of special resins and fine functional fillers, which have low friction and self-lubricating properties. Compared with traditional metal hard rails or plastic hard rails, it has a lower and more stable dynamic and static friction coefficient, avoiding inertia and force fluctuations caused by changes in the running speed or bearing capacity of the guide rail. The guide rail slides smoothly without crawling, and the machine tool accuracy is stable. In addition, the material has the advantage of excellent craftsmanship, convenient construction, high strength, high hardness and a long service life.

Technical parameters of low friction and wear-resistant coatings:

| Contents | Parameters | Remarks | |

| Friction Performance | Dynamica Friction | 0.03-0.10 | 1000mm/min 35N/cm² |

| Static Friction | 0.05-0.12 | 100s 35N/cm² | |

| Rigidity | Hardness | 88-90 | |

| Mechanical Property | Compression Strength MPa | 150-160 | |

| Elastic Modulus Gpa | 9-12 | ||

| Processing Property | Curing Shrinkage Rate | 0.001% | |

| Solidifying Time(20℃/min) | 75 |

Due to the unique material properties of low friction and wear-resistant coatings, they can replace ordinary plastic and metal friction media in the application of hard rails and guides, achieving better friction performance and more stable accuracy. At the same time, they can also be used for construction and repair of static pressure, bearings, etc.